|

|

Minebea MIS2UR-V2 Midrics 2 Indicator for Midrics bench and Floor Scales |

|

| The Indicator for the bench and floor scale Midrics® has proven itself in a variety of industries such as the food, pharmaceutical, chemical, electronic and metal industries. Boasting a long product lifetime, it is robust and easy to clean. Depending on the application, more ... |

|

Scales >

Indicators & Remote Displays >

Indicators & Remote Displays

|

|

|

|

|

|

Optional Warranty

|

Features

The Indicator for the bench and floor scale Midrics® has proven itself in a variety of industries such as the food, pharmaceutical, chemical, electronic and metal industries. Boasting a long product lifetime, it is robust and easy to clean. Depending on the application, the weight indicator can be set up independently from the location of the platform and can even be mounted on a stand.

Weight Indicators Midrics®

Display: backlit, 14-segment, 20 mm LCD for weight readouts

Integrated A/D-converter for connecting analog platforms

Material: AISI 304 stainless steel

Optional RS-232, RS-485, RS-422, 4-20mA, Digital I/O

- Applications: Classification, Counting, Fill quantity control, Filling and Dosing, Formulation and Weighing

- Certifications: ATEX, NTEP and OIML

- Smart software applications - Easy-to-use application software programmes for a variety of uses, such as counting, checking and pre-packaging checking, are pre-installed as a standard feature.

- Versatile interfaces - Optimal connectivity and integration into existing systems, for example via RS 232, RS 485/422, analogue 4–20 mA, digital inputs/outputs, Ethernet TCP/IP "Power on, weigh; job finished." An industrial scale has to be that simple to operate, and at the same time totally reliable and easy to clean. A lot of manufactures can offer one feature or another, but the new Midrics® from Minebea Intec has it all. From incoming inspection and shipping to production, warehouse management and packaging. And what does all this performance cost? A lot less than you might think!

- Easy to operate - Have you seen the indicators that require a course of studies just to operate them? They offer countless gimmicks that have no practical benefits and provide more distraction than real help. We could have added features like that to the Midrics®, but we build indicators for people who want to get their work done as quickly and reliably as possible. We left out the bells and whistles, and concentrated on giving you what you need for your daily tasks - which left us free to provide it all in the best possible quality. See for yourself.

- Easy to clean - Once the work is finished, it’s clean-up time. This is one of the hardest tests for an indicator because in industry, cleaning the equipment is not likely to be a gentle process. We know: if you try to save on materials and workmanship, you wind up paying double for it later. We prefer to do the math, and do it right. The Midrics® is made with only the highest quality materials, and is designed specifically to be both rugged and easy to clean - and it looks great, too! The new Midrics®- Because it makes weighing so easy.

Midrics® Scale Indicator MIS 1

Display: backlit, 14-segment, 20 mm LCD for weight readouts

Optional RS-232, RS-485, RS-422, 4-20mA

Midrics® Scale Indicator MIS2

Display: backlit, 14-segment, 20 mm LCD for weight readouts, bar graph

Connection for bar code scanner; battery operation

Optional RS-232, RS-485, RS-422, 4-20mA, Digital I/O

Applications: weighing, counting, checkweighing, classification (into three or five classes), totalizing, net-total, weighing in percent, neutral measurement

Weight:

20.00 lb

|

|

Other Minebea Intec Midrics Indicators

|

Specifications

|

lEVEL 1 |

lEVEL 2 |

|

MIS1UR-V1 |

MIS1U-L9 |

MIS2UR-V2 |

MIS2U-L9 |

| Internal battery pack |

- |

Included |

- |

Included |

| Keyboard |

5 keys |

23 keys |

| Display |

14 segments

20 mm weight readout |

14 segments

20 mm weight readout

plus application symbols |

| Legal for Trade |

NTEP Class II CC # 08-097A3 |

| Weighing |

YES |

YES |

| Data transfer to printer/PC |

YES |

YES |

| Counting |

- |

YES |

| Percentage weighing |

- |

YES |

| Averaging |

- |

YES |

| Checking/classification |

- |

YES |

| Totalising |

- |

YES |

| Net total |

- |

YES |

| Identifier (4 × 40 characters) |

- |

YES |

| Date/Time (optional) |

YES |

YES |

| Internal Alibi memory (optional) |

YES |

YES |

| IP protection rating |

IP65 |

IP65 |

| Load cell connection |

Supply voltage: 8.4 V

Sensor technology available: 4 or 6 wire technology |

| Bridge impedance |

83 ohm up to 2,000 ohm |

| Measuring signal hub |

0 mV to 29.4 mV |

| Measurement signal / calibration value |

min. 0.672 µV/e |

| Sensitivity |

Max. 4 M divisions (internal) |

| Net weight |

(Approx.) 2.3 kg |

|

|

|

|

* within the 48 continental US States

|

|

Optional Accessories

more info

|

Minebea A19 485 interface for CIXS3 or CAIXS2 Explosion Proof Indicator

Minebea A19 485 interface for CIXS3 Explosion Proof Indicator

|

|

more info

|

Minebea M26 Cable from CIXS3 or CAIXS2 to IS-X

Minebea M26 Cable from CIXS3 to IS-X

|

|

more info

|

Minebea YDH01CWSUS Post mount assembly for 10 in x 10 in platforms, 13 in High

13" Column for attaching indicator to platform for sizes 12.6" x 9.4".

|

|

more info

|

Minebea YDO02C-232, UniCOM - RS232 Interface

Minebea YDO02C-232, UniCOM - RS232 Interface

|

|

more info

|

Minebea YDH02CWSUS Post mount assembly for 12 in x 12 in platforms, 19 in High

19.7" Column for attaching indicator to platform for sizes 15.7" x 11.8" and 19.7" x 15.7".

|

|

more info

|

Minebea YDO02C-485, UniCOM - RS422 or RS485 Interface

Minebea YDO02C-485, UniCOM - RS422 or RS485 Interface

|

|

more info

|

Minebea YDH03CWSUS Post mount assembly, for 18 in x 18 in platforms, 29 in High

29.5" Column for attaching indicator to platform for sizes 19.7" x 15.7".

|

|

more info

|

Minebea YDO02C-DIO Digital 5 Input / 5 Output Opto Isolated

Minebea YDO02C-DIO Digital 5 Input / 5 Output Opto Isolated

|

|

more info

|

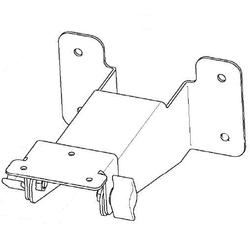

Minebea YDH12CWSUS Indicator Holder for Midrics DC, ED, and FE Series

Stainless steel holder for bench top fixing, only for platform sizes 9.4" (DC), 15.7" x 11.8" (ED) and 19.7" x 15.7" (FE).

|

|

more info

|

Minebea YDO02C-AO Analog Current Output, 0-20 mA, 0-10V, 16-bit

Minebea YDO02C-AO Analog Current Output, 0-20 mA, 0-10V, 16-bit

|

|

more info

|

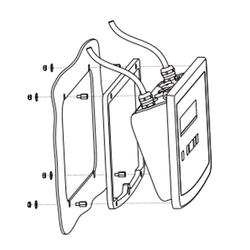

Minebea YDH02CISUS Wall Mounting for Midrics/Signum Series

Brackets for wall mounting, stainless steel, tiltable indicator.

|

|

more info

|

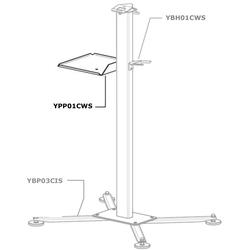

Minebea YPP01CWS Printer stand for YDH03CISUS column

Minebea YPP01CWSUS Data Printer

Features

The following can be computed/printed out using this Sartorius data printer:

- Number of weighing operations

- Mean value

- Standard deviation

- Variation coefficient

- Minimum value/weight

- Maximum value/weight

- Difference between the maximum and minimum value/weight

Data are transferred either automatically or manually by pressing a key.

Built-in real-time clock

Built-in statistics program. These programs can be individually selected to meet your needs.

Counter for consecutive numbering of transactions can be activated.

High contrast LCD that shows the date or time as well as the current transaction number.

Integrated rechargeable batteries with battery level indicator.

Ultrafast print head.

Runs on the balances power, no separate power supply necessary.

Easy to change paper roll and ink ribbon cassette.

|

|

more info

|

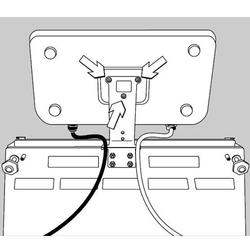

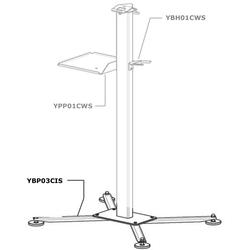

Minebea YBP03CIS 4-leg Base For YDH03CISUS Column

Minebea YBP03CIS 4-leg Base For Column

Dimensions of the floor plate (LxW) 220mm x 135mm

Equipment supplied: floor –mounted column incl. fasteners (3 M4x 8 screws, screws with thread designed for wood acc. to DIN571-?6x50-A2, 4 dowels ? 8x40)

Base for installing floor-mounted column or bench stand

You can attach the base (YBP03CIS), if needed, to the bottom of the column.

At each end of the base, hook the ends of the two feet together; use the 4 Allen screws to attach the base to the column.

The illustration shows a view of the column and base from the bottom.

|

|

more info

|

Minebea YDH02CISUS Wall Mounting for Midrics/Signum Series

Brackets for wall mounting, stainless steel, tiltable indicator.

|

|

more info

|

Minebea YAS07CI Panel (Cabinet) Mount Kit

Minebea YAS07CI Panel (Cabinet) Mount Kit

|

|

more info

|

Sartorius YDP20-0CE Strip Printer, with statistics, date, and time functions

The YDP20-0CE data printer is designed to receive

weighing data from a connected weighing instrument

and print it on plain paper (roll width:

57.5 mm), with up to 24 characters per line.

The data printer is equipped with a real-time clock.

After the printer has been configured according to

the required settings, it is suitable for use as auxiliary

apparatus in legal metrology.

The YDP20-0CE data printer meets the quality standards

of the chemical and pharmaceutical industries, in

compliance with the requirements of GLP (Good Laboratory

Practice) and GMP (Good Manufacturing Practice).

In addition to recording individual weighing data, the

data printer can generate a statistical evaluation of

weighing data. All values transferred from an on-line

weighing instrument are stored. The following can be

printed out, depending on your printer configuration:

– Number of weighing operations

– Mean value

– Standard deviation

– Variation coefficient

– Lowest measured value

– Highest measured value

– Difference between lowest and highest measured values

– Date and time

Data is transferred either automatically or manually, at

the press of a key.

The following can be computed/printed out:

- Number of weighing operations

- Mean value

- Standard deviation

- Variation coefficient

- Minimum value/weight

- Maximum value/weight

- Difference between the maximum and minimum value/weight

Data are transferred either automatically or manually by pressing a key.

Built-in real-time clock

Built-in statistics program. These programs can be individually selected to meet your needs.

Counter for consecutive numbering of transactions can be activated.

High contrast LCD that shows the date or time as well as the current transaction number.

Integrated rechargeable batteries with battery level indicator.

Ultrafast print head.

Runs on the balances power, no separate power supply necessary.

Easy to change paper roll and ink ribbon cassette.

|

|

|

|

|

|

|

|

|