Stop Measuring Viscosities the Hard Way

Are you struggling with an expensive rheometer that only produces unstable

results when testing low viscosity (e.g. below 100 mPa•s) samples? Drawing on

A&D’s proven sensor technology for high-resolution analytical balances, the

RV-10000A Tuning Fork Vibro Rheometer is a breakthrough alternative to

conventional methods in the research of non-Newtonian fluid properties,

especially for ease and precision in low viscosity measurements

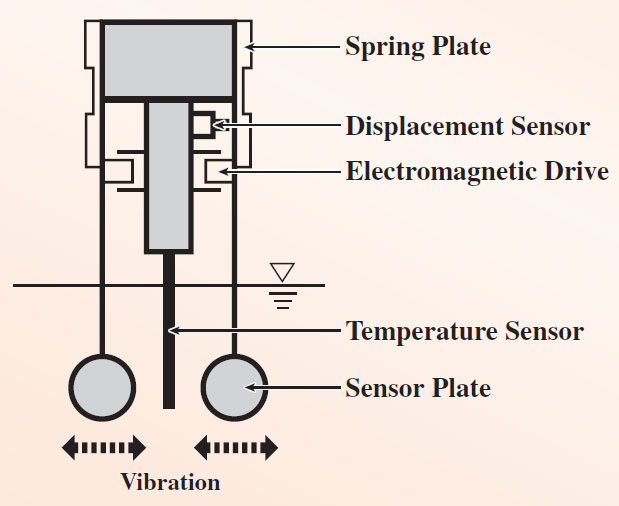

Tuning Fork Vibro Rheometer - Principle of Operation

Two thin sensor plates in a tuning fork arrangement are driven with electromagnetic

force to vibrate at their natural (resonant) frequency of 30 Hz within the sample

fluid. Viscosity is then calculated based on the proportional relationship between the

viscous resistance of the sample fluid and the amount of electric current required to

drive and maintain the sensor plates at a constant vibration amplitude.* 1

This is an application of the electromagnetic equilibrium mechanism employed by

A&D’s high-end weighing devices, including microbalances whose scale interval is as

small as 1 ìg (1/1,000,000 of 1 g).

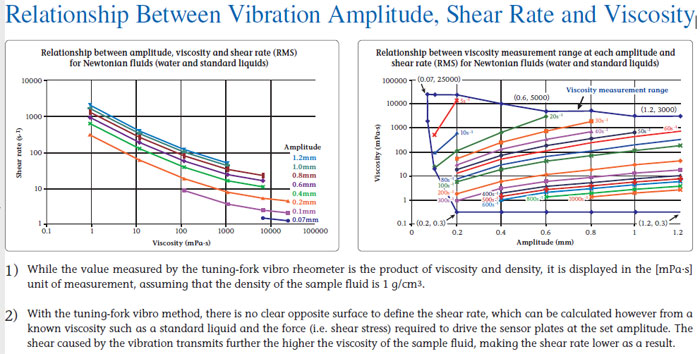

How the shear rate is changed

The sensor plate amplitude of the RV-10000A can be altered between the minimum of

0.07 mm and the maximum of 1.2 mm (peak to peak) while the frequency is kept at

30 Hz, which will cause variation in shear rate. By this means, you can easily quantify

the viscous behaviors of non-Newtonian fluids in response to different shear rates.

The tuning fork vibro method is recognized as a Japanese industrial standard for viscosity measurement of liquids (JIS Z8803).

The viscometer that uses this method is also accredited as a standard device for the Japan Calibration Service System (JCSS)

along with capillary and rotational viscometers

Advantages

Wide Continuous Measurement Range—From 0.3 mPa• s

The RV-10000A has a single viscosity detection system that can measure from very

low to high viscosity without interruption (max. 0.3 to 25,000 mPa•s), which realizes

high versatility and allows measurement of various types of fluids with just one

instrument. It also allows continuous monitoring of viscosity variation with time,

temperature as well as shear rate.

Extremely High Sensitivity

The sensor sensitivity heightened through sharp resonance phenomena even detects viscosities around

the level of water with unparalleled precision. Such sensitivity even realizes measurements, for

example, for finding the cloud point of surfactants and controlling the drinking sensation of beverages.

Excellent Repeatability

The RV-10000A achieves repeatability as high as 1% of the measured value (by standard deviation) for

the entire measurement range, providing you with consistent results and enabling reliable

comparisons of those results.

Relationship Between Vibration Amplitude, Shear Rate and Viscosity

Simultaneous Measurements of Temperature and Viscosity

The temperature sensor (0 to 160 °C range) located between the two viscosity sensor plates

allows measurement of viscosity’s dependence on temperature as accurately as possible

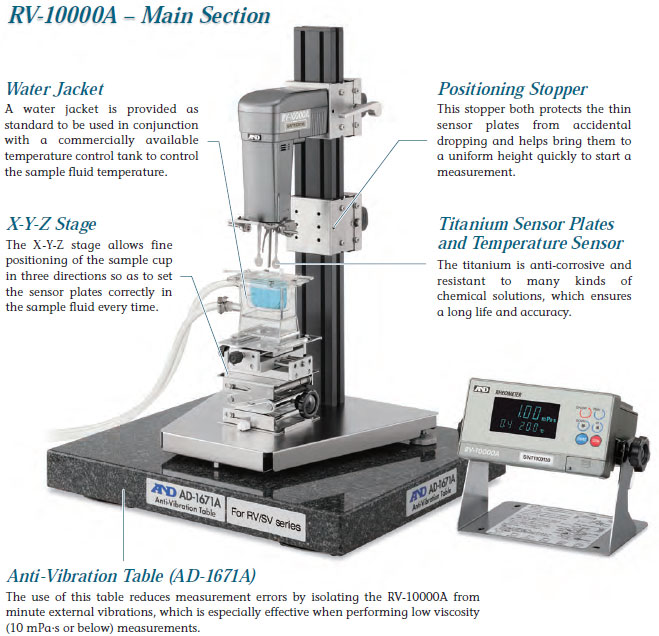

Sample Fluid Temperature Control

By using the provided water jacket with a

commercially available temperature control

tank, you can control the sample fluid

temperature (between 0 and 100 °C) in order to

measure the viscosity at a constant temperature

or see how the viscosity varies with temperature

Easy Setup and Very Quick Measurement

Compared with conventional methods, it takes much less time for you to set the

sample fluid, start measurement, and obtain the viscosity value (the RV-10000A

requires only 20 seconds to stabilize). Moreover, since the sensor plates have a very

small thermal capacity, they cause minimal temperature change to the sample fluid

upon immersion, also contributing to fast and stable viscosity measurement.

It is very easy to clean the sensor after

measurement as well – all you need to do is

wipe off the sample residue with alcohol.

Little Interference to the Sample Fluid

The low-frequency, low-amplitude vibration causes only minute displacement in the

sample fluid and keeps changes to its temperature and physical structure to a

minimum. This enables highly stable measurements of viscosity variations over a long

period of time. It also enables the measurement of fluids such as foams (e.g. whipped

cream) without breaking their tiny air bubbles or dispersion systems (e.g. colloids)

while they are settling

Measurements of Fluids in Motion

The two sensor plates vibrate in opposite directions,

meaning that even if the sample fluid is flowing or

being stirred during measurements, the errors of

each sensor plate are cancelled out by those of the

other. It is therefore possible, for example, to

measure the viscosity of a flowing fluid in a

production line and maintain data compatibility

between the laboratory and the field.

Easy Calibration by Yourself

Both one-point and two-point calibrations are possible using either viscosity standards

(available as accessories) or fluids of known viscosities. With the RV-10000A, there is

no need to spend time and money having the instrument calibrated by an outside

specialist.

Simplified Calibration Function

For a viscosity range around 1 mPa• s, a highly useful, simplified calibration function is available. You

only have to prepare purified water and perform a simple one-key operation, and the RV-10000A will

automatically calibrate itself using stored information on the viscosity of purified water at each

temperature.

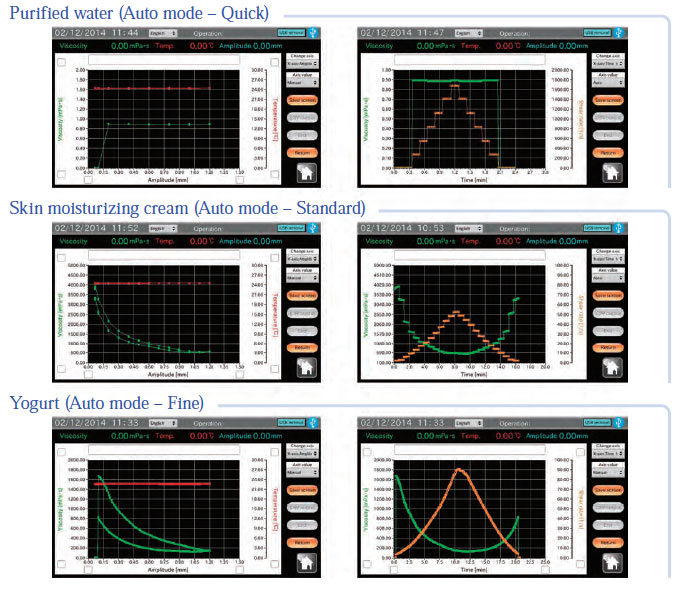

RV-10000A – Controller Section

The dedicated controller can automatically

change the sensor plate amplitude and take

data in the manner you programmed. It

also shows and graphs measured values in

real time so that viscosity changes as a

function of time, temperature, and/or shear

rate* 4 become plainly visible.

The results can be saved in CSV format and

graph screens as JPEG images in a USB

flash drive.

In Auto mode, the sensor plate amplitude automatically

goes from 0.07 mm to 1.2 mm and back to 0.07 mm again

according to one of three preset types of measurement

conditions: Quick, Standard and Fine modes, from which

you can make a choice of how finely to change the

amplitude (8, 13 or 114 levels) and how long to take for the

measurement (7.5, 25 or 60 minutes in total).

Auto mode helps when you want to take a quick scan of the

physical properties of the sample fluid.

Program mode allows you to more freely design the

measurement conditions, by setting either amplitude

changes in steps (Step mode) or two amplitude points so

that it linearly (in scales of 0.01 mm) increases and then

decreases between them (Fine mode). This mode is

especially useful for testing the sample fluid within a

specific amplitude (shear rate) or viscosity range.

The measurement conditions set in Step mode can be saved

for later measurements with the same conditions (up to 10

programs).