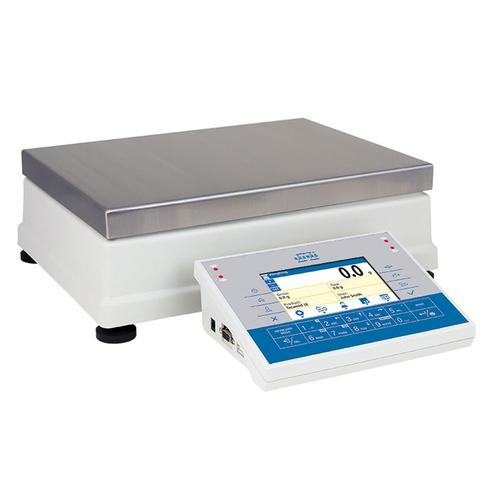

PM series balances are equipped with an innovative measuring system based on RADWAG MonoBLOCK® technology. Use of the new measuring system, which is a subject matter of RADWAG patent, guarantees stability of repeatability over time at a range sd<1d. The unique measuring system solution is characterized with great resistance to ambient conditions change. An in-built 4-point protection system prevents balance overloading, this ensures safety in case too heavy load is applied onto the weighing pan.

- new RADWAG MonoBLOCK® sensor;

- unrivalled repeatability of indications;

- weighing of heavy loads with maximum accuracy;

- intuitive operation guaranteed by a membrane keyboard;

- fast mass measurements;

- robust mechanical design – new lower weighing platform;

- improved ergonomics – two types of weighing terminal for selection.

Balance offers possibility of weighing loads outside the weighing platform (so called under-pan weighing). This is an alternative for weighing loads with non-standard dimensions and shapes or those generating magnetic field.

Balance offers possibility of weighing loads outside the weighing platform (so called under-pan weighing). This is an alternative for weighing loads with non-standard dimensions and shapes or those generating magnetic field.

- Reliable Results and High Measurement Precision Excellent measurement parameters and performance enable applying PM C32 balances in laboratories and various branches of industry.

- Radwag MonoBLOCK™, an Innovative Weighing System The cutting edge technology of the measuring system guarantees stability of repeatability in time, where sd<1, and a significant resistance to ambient conditions.

- Weighing Heavy Loads With the Maximum Accuracy It is possible to work with samples of different weight values, from few grams to several kilograms, wherein the highest measurement accuracy and excellent result repeatability are maintained.

- Reliability and Safety 4-point protection system prevents balance overloading, this ensures safety in case too heavy load is applied onto the weighing pan. Robust design allows to operate the device even in the most challenging ambient conditions.

- Ease of Use and Maximum Comfort of Operation 5" color screen enables intuitive operation and easy access to numerous applications and functions. PM C32 program allows screen layout customization.

- Automatic Adjustment Internal adjustment system guarantees the highest accuracy and reliable measurements results.

- Touch-Free Operation Two programmable proximity sensors can be assigned with any function or application. The given function when assigned is both run and operated touch-free.

- Numerous Options of Data Management The instrument enables saving all completed measurements data as complex reports and graphs.

- LABELLING - Marking products with the right symbols contributes to quick and reliable identification. The balance/scale usually transfers product mass or product quantity to the label printer. The transferred value is printed with the following information: bar code, pictogram, content, address etc. In laboratory the labelling is performed in a semi-automatic mode, for industry in an automatic one (dynamic scales).

- PLUS/MINUS CONTROL - Control of samples mass carried out with reference to specified MIN and MAX thresholds. The weight is considered to be correct if it is comprised within threshold values. A graphic visualisation of weighing result is displayed in a form of a bar graph.

- PERCENT WEIGHING - Percent Weighing function is used for comparision of measured products with mass standard. Mass of a mass standard may be a numeric value taken from a database or it may be determined through a measurement process. Each measured product is compared to mass standard, mass of which is presumed as a model 100% ideal mass. For products weighing less than the mass standard, obtained results are lower than 100%, for products weighing more, the obtained results are greatly exceeded.

- PARTS COUNTING - Function using mass measurement for determination of measured items quantity. Mass of a single item is required for this process. It may be either estimated through weighment or taken from a database. For items counting the following algorithm is used: all items mass / single item mass = quantity. Function operation is supperted by a mechanism of Automatic Correction of Accuracy. This allows to update single item mass in course of the process. To a certain extend Automatic Correction of Accuracy eliminates error which may be a result of different mass values of seemingly alike single elements. For industry solutions items counting may be simultaneously carried out with checkweighing and dosing thus industry solutions feature audio signalling base informing that specified number of items has been weighed. It is possible to apply weighing systems using few platfroms of different MAX capacities and different accuracies.

- STATISTICS - Statistiscs function registers and analyses performed measurements. This supplies the user withthe following information: Max and Min standard deviation, average value, variance, range et.

- IR SENSORS - Programmable function supporting the weighing process through control of the following options: sliding weighing chamber doors, printout, zeroing, tarring etc. Especially appreciated wherever preventing the balance from soiling is important.

- UNDER-PAN WEIGHING - The solution enables weighing with use of a stand, which is advisable for loads of non-standard shapes and dimensions and those that generate magnetic field

- GLP PROCEDURES - Diagnostic function allowing to objectively document performed measurements. GLP procedures may be either presented in a short report form or extended one.

- REPLACEABLE UNIT - Replaceable units.

- ALIBI MEMORY - "ALIBI" memory enables saving and storing up to 100000 measurements. Measurements are saved automatically upon each pressing of the key. There is no need for any additional operations or changing settings. The following data related with the measurements is saved: measurement date; measurement time; result (mass); tare value; operator carrying out the measurement (logged in); product name. The software saves the measurement in a so called loop, i.e. when the measurement no. 100001 is saved, the measurement 1 gets automatically deleted from the memory. Measurements saved to balance memory cannot be deleted. You can preview and print out the data saved to the ALIBI database.

| Standard Model |

PM 10.C32

WL-223-0005 |

PM 15.C32

WL-223-0006 |

C32.25.PM

WL-223-0025 |

PM 35.C32

WL-223-0007 |

PM 50.C32

WL-223-0008 |

PM 60.05.C32

WL-223-0009 |

PM 60.1.C32

WL-223-0012 |

| Price |

$2,488.00

|

$3,768.00

|

$2,139.00

|

$2,395.00

|

$3,767.20

|

$4,661.00

|

$4,406.00

|

| Capacity x Readability |

10 kg x 0.01 g |

15 kg x 0.01 g |

25 kg x 0.1 g |

35 kg x 0.1 g |

50 kg x 0.1 g |

60 kg x 0.5 g |

60 kg x 1 g |

| Preload |

1 kg |

1.5 kg |

2.5 kg |

3.5 kg |

5 kg |

- |

- |

| Minimum load |

0.5 g |

0.5 g |

5 g |

5 g |

5 g |

0.5 g |

1 g |

| Verification scale interval [e] |

0.1 g |

- |

1 g |

1 g |

1 g |

- |

- |

| Tare range |

–10 kg |

–15 kg |

–25 kg |

–35 kg |

–50 kg |

–60 kg |

–60 kg |

| Repeatability (5% Max)* |

0.004 g |

0.004 g |

0.04 g |

0.04 g |

0.04 g |

0.2 g |

0.4 g |

| Repeatability (Max) |

0.01 g |

0.015 g |

0.1 g |

0.1 g |

0.15 g |

0.4 g |

0.8 g |

| Linearity |

+ 0.03 g |

+ 0.03 g |

+ 0.3 g |

+ 0.3 g |

+ 0.3 g |

+ 1.5 g |

+ 3 g |

| Sensitivity temperature drift** |

2 x 10-6 / oC x Rt |

2 x 10-6 / oC x Rt |

2 x 10-6 / oC x Rt |

2 x 10-6 / oC x Rt |

2 x 10-6 / oC x Rt |

2 x 10-6 / oC x Rt |

2 x 10-6 / oC x Rt |

| Minimum weight (U=1%, k=2) |

0.82 g |

0.82 g |

8.2 g |

8.2 g |

8.2 g |

41 g |

82 g |

| Minimum weight (USP) |

8.2 g |

8.2 g |

82 g |

82 g |

82 g |

410 g |

820 g |

| Adjustment |

Internal Calibration |

| Stabilization time |

3 s |

1 s |

3 s |

| OIML Class |

OIML Class II |

- |

OIML Class II |

OIML Class II |

OIML Class II |

- |

- |

| Indicator fastening |

1.5 m cable (Standard Models) |

| Terminal mode |

PUE C32 indicator |

| Display |

5" graphic color |

| Keypad |

22-key membrane |

| Protection class |

IP 43 |

| Databases |

5 |

| Touch-free operation |

2 programmable proximity sensors |

| USB-A |

1 |

| USB-BA |

1 |

| RS232 |

2 |

| Ethernet |

10 / 100 Mbit |

| Wireless connection |

802.11 b/g/n |

| Power supply |

12 ÷ 16 V DC |

| Power consumption |

15 W |

| Operating temperature |

+10 ÷ +40 oC |

| Atmospheric humidity*** |

40 ÷ 80 % |

| Transport and storage temperature |

–10 ÷ +50 oC |

| Weighing pan dimensions |

200 x 185 mm |

200 x 185 mm |

347 x 259 mm |

347 x 259 mm |

347 x 260 mm |

500 x 400 mm |

500 x 400 mm |

| Weighing device dimensions |

508 x 296 x 115 mm |

508 x 296 x 115 mm |

508 x 296 x 115 mm |

508 x 296 x 115 mm |

508 x 296 x 115 mm |

640 x 400 x 115 mm |

640 x 400 x 115 mm |

| Net weight |

10 kg |

10 kg |

11 kg |

11 kg |

11 kg |

17 kg |

17 kg |

| Gross weight |

12.2 kg |

12.2 kg |

15.5 kg |

13.2 kg |

13.2 kg |

19 kg |

19 kg |

| Packaging dimensions |

520 x 520 x 280 mm |

520 x 520 x 280 mm |

520 x 520 x 280 mm |

520 x 520 x 280 mm |

520 x 520 x 280 mm |

700 x 600 x 200 mm |

700 x 600 x 200 mm |

Rt net weight

* repeatability is expressed as a standard deviation from 10 weighing cycles

** parameter determined in the following temperature range: +15 ÷ +35 oC

*** non-condensing conditions

In accordance with type approval, the balance parameters are maintained in temperature range: +15 ÷ +35 oC.

Optional Accessories

Weighing Tables

- granite antivibration table

- antivibration tables for laboratory balances

Peripheral Devices

- Epson dot matrix printer

- barcode scanners

- WD-6 LCD display

Electrical accessories

- ZR-02 power supply with battery

Cables, Converters

- P0108: RS 232 cable (balance-computer)

- P0167: RS 232 cable (balance-computer)

- P0151: RS 232 cable (balance - Epson printer)

- AP2-1 power loop output

- IN/OUT cables

Draft shields and anti-draft chambers

- storage case for PM 10 kg, PM 15 kg, PM 35 kg, PM 50kg, PM.KB balances

|