|

The FG-7000 Series digital force gauges are loaded with functionality to simplify your compression and tension testing needs. The multiple-language FG-7000’s provide menu programming for easy selection and set-up of the instrument to your desired requirements. Three modes of operation are selectable: Track mode for live readings, Peak mode for displaying the peak reading that remains until a higher peak is sensed, and Auto Peak mode which is similar to Peak mode except the peak on the display will additionally reset after a programmed time period. Programmable limits provide a quick visual and audible indication if a test passed or failed on the LCD. In addition, the comparator output can be set up for integration of the instrument into your quality system for repetitive testing such as on a production line.

|

|

The FG-7000T digital torque gauge measures bidirectional torque via a remote sensor with an integrated chuck. The tester can be used for a wide range of applications including fastener assembly, bearing friction testing and much more.

Four selectable measuring modes include: Track mode for live readings, Peak mode for displaying the maximum reading, First Peak where only the initial peak is recorded once a decrease is sensed and Preset which initiates user-programmed tolerance alarms for go/no go testing. The display has two selectable operations, numerical view or graphical view with torque direction bar graph. In graphical view when alarm tolerances are set, the process is plotted in relation to the upper and lower limit graph lines. Combined with the go/no go icons, a simple pass/fail determination is recognized.

The FG-7000T features memory for peak readings or continuous data logging. Data can be viewed on the screen or transferred the included Windows software. 1,000 point memory with definable groups allows for multiple tests to be recorded and easily separated upon loading. In addition, the comparator output can be set up for integration of the instrument into a quality system for repetitive testing such as on a production line.

The FG-7000T’s rugged aluminum housing is designed to fit perfectly in the operator’s hand for portable testing. The large back-lit, 180° auto-reversible display, CW/CCW directional bar graph, combined with the dual labeled key pad allows for usage of the gauge in various positions while still being able to easily view and operate. These features make the FG-7000T the ideal torque instrument for applications such as closing or opening analysis of containers, valves and door hardware, failure or destructive torque testing, or almost any torque testing requirement involving incoming quality inspection, finished goods testing to R&D.

Features

- Display operates in numerical or graph modes, both include a directional bar graph

- Graph mode combined with set point tolerances provides instant recognition of process relation to upper and lower limits

- Four Modes of Operation: Peak, First Peak, Preset and Track Mode

- Memory with group categorization to easily separate your tests for review and later download

- Free software for viewing, graphing and analyzing data on PC

- Large, Backlit, Auto-Reversible display with various icons of test status aids user during testing

- Programmable High/Low tolerances combined with comparator NPN/PNP output allow usage in quality control production lines

- Supplied with factory calibration certificate

|

The FG-7000T is supplied as a complete kit including torque tester with chuck, AC Adapter/Charger, USB cable, calibration cert in a fitted carrying case.

|

EDMS Data Acquisition Software (free download on website)

Allows full testing of FG Series Force Gauges with live analysis

of the test results. Users can set a delay or a time period for the

test data to record as well as begin or end if a load threshold is

reached. The load can be inverted so the graph shows the resultant

force in the direction desired. Average and peak readings

are automatically calculated, but the user can zoom in on a section

of a graph and recalculate the new average and peak over

the selected portion of the test. Besides acquiring live data, the

EDMS program can also upload previously stored readings from

the gauge. Additionally, the software provides the ability to easily save the data set to a spreadsheet file, plus save the resultant graph as a photo for later review.

| Model |

FG-7000T-1 |

FG-7000T-2 |

FG-7000T-3 |

| Price |

$1,102.50

|

$1,102.50

|

$1,192.50

|

| Capacity X Readability |

8.9 x 0.005 lbf-in |

44.3 x 0.01 lbf-in |

88.5 x 0.01 lbf-in |

| 1 x 0.001 Nm |

5 x 0.001 Nm |

10 x 0.01 Nm |

| 100 x 0.1 N-cm |

500 x 0.1 N-cm |

1000 x 1 N-cm |

| - |

3.68 x 0.001 lbf-ft |

7.38 x 0.001 lbf-ft |

| Chuck Size |

1-10 mm

0.034 to 0.39 in |

1-10 mmm

0.034 to 0.39 in |

2-13 mmm

0.079 to 0.512 in |

| Accuracy |

± 0.3% F.S. |

| Selectable Units |

N-m, N-cm, kgf-cm, lbf-in (Depending on Range) |

| Overload Capacity |

120% of F.S. (LCD flashes beyond 110% of F.S.) |

| Measurement method |

Peak, First Peak Preset or Track Mode |

| Data Sampling Rate |

1000 Hz |

| Display |

160 x 128 dot matrix LCD with LED Backlight |

| Display Update Rate |

10 times/second |

| Memory |

1000 data |

| Set Point |

Programmable high and low limits |

| Battery Indicator |

Display flashes battery icon when battery is low |

| Power |

3.6VDC 800mAH Ni-MH rechargeable batteries |

| Battery Life |

Approximately 16 hours continuous use per full charge |

| Charger / Adapter |

Universal USB/BM charger, Input: 110 ~ 240VAC |

| Outputs |

USB, Serial Port RS-232, High & Low Limit NPN |

| Operating Temperature |

14 to 104°F (-10 to 40°C) |

| Housing Material |

Aluminum |

| Storage Temperature |

-4 to 122°F (-20 to 50°C) |

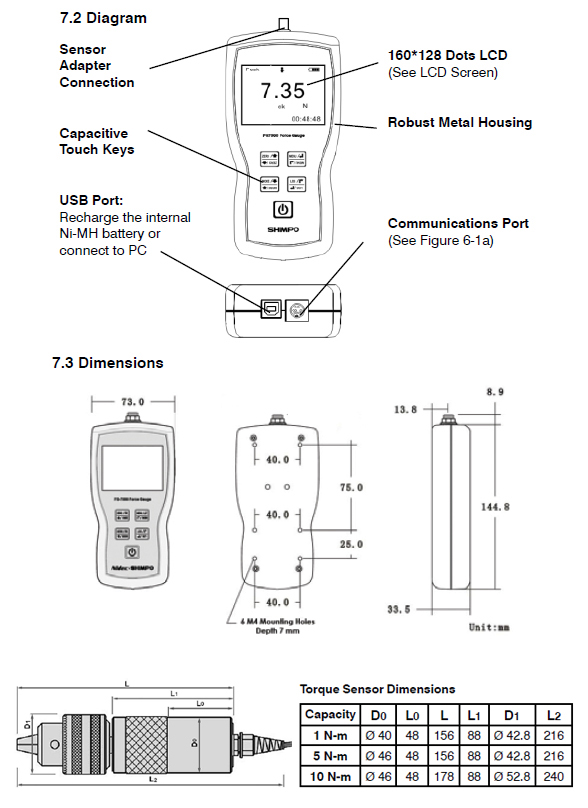

| Dimensions |

5.7 x 2.9 x 1.4" (145 x 73 x 35.5 mm) |

| Weight |

NET3.7lbs (1.7 kg)

GROSS 5.5 (2.5 kg) |

| Warranty |

1 year |

|