The DFS3 Series offers the best price performance of any digital force gauge available today. This compact, easy-to-use force gauge is designed for basic and complex applications. Ideal for handheld or test stand applications, the DFS3 may be equipped with integral loadcells or smart remote sensors for load measurement or torque measurement.

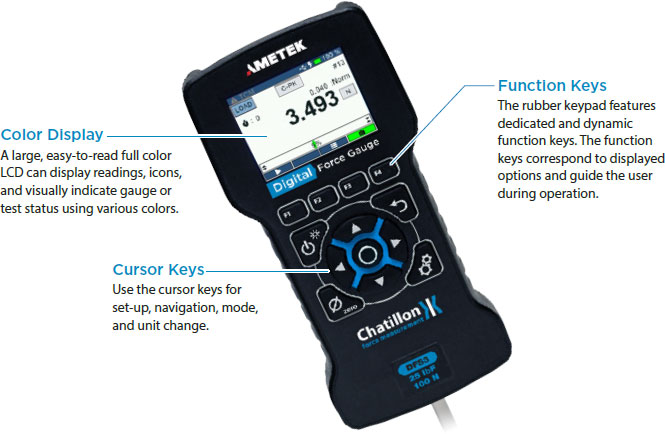

Measurement accuracy is better than 0.1% full scale in integral load cell models. A large, easy-to-read, high resolution, full color LCD display supports a variety of standard gauge functions including normal and peak readings, high/low limits, setpoints, pass/fail results, statistical results, load averaging, % and sharp break detection, loadcell actuation and direction. Loads are displayed in ozf, gf, lbf, kgf and N units. The display can be inverted and displayed results may be “hidden” from the operator. The DFS3 also offers password protection for gauge set ups.

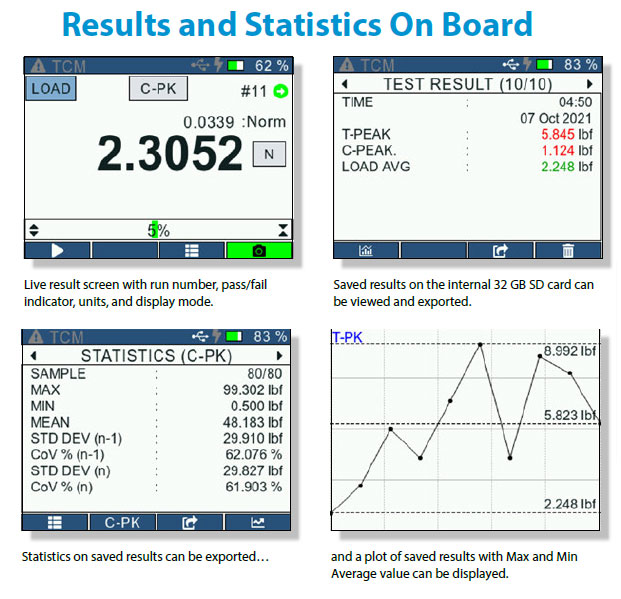

Comprehensive Results

The DFS3 Series supplies you with comprehensive results that are

easy to view and understand. The gauge displays:

- Measured Result with Units:

- Peak Tension and Compression.

- Break Tension and Compression.

- Load Average/Time.

- Operating Mode.

- Pass-Fail Result.

- High and Low Load Results.

- Saved Results.

- Statistical Calculations:

- Average with MIN and MAX Results.

- Cv with Average and Standard Deviation.

- Standard Deviation.

- Graphical representation of saved results.

Outputs

The DFS3 Series comes standard with a USB-C connection. The USB interface allows communications with a PC.

Calibrate and Verify Status

The DFS3 Series incorporates flash memory. You have immediate access to battery conditions, including estimated battery life remaining. You can also view loadcell status, including the number of overloads that have been applied to the gauge

Time Method

The Time method allows you to establish your load averaging based on a load threshold and time duration. The load threshold determines the start of the averaging, while the time duration defines the length of the test period. The gauge will begin taking readings when the threshold is reached and will continue to take and average readings until the time duration has expired.

Battery Life

The extraordinarily long battery life of the DFS3 reduces the need for continuous recharging. The dimming functionality of the DFS3 provides a battery life of 30 hours when the dimming is off while turning the dimming on will provide a full 40 hours of battery life.

Functions and Features

Unique User Interface

Easy to use, single layer user interface. No deep menu structure! Operate and set-up the DFS3 to perform your tasks. Fast and intuitive! The high resolution display features brightness adjustments and can be inverted when required. The display can even be “hidden” at the press of a button. A load bar graph indicating load direction, measured load, and safe load helps prevent overloads: the load bar changes from green to red to indicate proximity to load cell capacity. The integral loadcells feature mechanical overload protection at 150% Full Scale.

Dependable Measurements

The DFS3 Series features an integral loadcell sensor that delivers repeatable, accurate results. The innovative load bargraph shows dynamic load, direction of load and warns you of pending overload conditions. Smart technology in the gauge even keeps track of overload history to aide in maintenance and troubleshooting.

Automate with ForceTest (Free with your Chatillon DFE3)

- Expand Functionality - The ForceTest software expands the functionality of your Chatillon DFE3 force gauge. This easy-to-use Windows based software interfaces directly to your digital force gauge enabling you to automatically perform tests and graphs using a personal computer. Test results can be followed directly on the screen while the test is running.

- Intuitive User Interface - The colorful and intuitive user interface ensures that tests are simple to set up. Custom chart colors can be set for easy viewing. Units of measure, fonts, titles and force measurement resolution can also be customized through the ForceTest software.

- Easy Export and Reporting - Test results are presented in a preadsheet format allowing you to analyze and manipulate data and perform common mathematical and statistical calculations. Results may be displayed graphically versus time. Tabular results are displayed and can be used to create relationships, queries or used to produce reports. Test results can be exported to a .csv format. Graphs and test results can also be exported directly to PDF and Word formats.

- Wide Variety of Options - Force at maximum in a time window, average force and much more can be captured using the ForceTest software. Basic force measurement such as tensile and compression test formats, pull to limit, and compress to limit are performed by clicking just a few buttons.

- Reduce Setup Time - To reduce setup time the ForceTest software offers pre-set templates. It also empowers its user to auto load the latest test performed, and to open previously saved tests for use as template for new tests.

|

|

AFM & AQM

Versatility and Simplification The external sensors: AFM external load cell, and the AQM external torque transducer, can be used together with our force gauge DFS3 to offer ultimate flexibility when performing different types of tests in various applications without having to constantly change settings. All settings can be preconfigured so that the sensors are ready for use, and this especially increases the effciency when doing repeated testing day-after-day.

Up to two external sensors can be connected in the DFS3 force gauges. Together with the internal sensor., the full set-up provides a 3-in-1 device. The force gauge shows the results from one sensor at a time, so that there is no doubt as to which sensor the results come from.

It is easy to connect the two external sensors - they both have an ADC inline box, which ensures a stable digital signal and enables the force gauge itself to identify them with a single click. The digital communication offers an improved accuracy and keeps the calibration information stored within the external device, meaning it can be used by other DFS3 gauges without affecting readings. This makes it plug-and-play.

- External loadcells AFM - Capacities from 0.5lbf to 1000lbf (2.5N to 5000N) Accuracy: 0.1% FS

- External Torque Transducers AQM - Capacities from 3in-lbf to 200in-lbf (0.35 Nm to 20 Nm) Accuracy: 0.3% FS

AFM & AQM with the DFS3

Unique User Interface The AFM and AQM sensors are automatically recognized by the DFS3 force gauge. The integrated electronics associated with the sensors contain all the calibration parameters necessary to guarantee the best measurement precision and metrological monitoring. In addition, potential overloads, dates, and values are also stored in memory and displayed.

Always up to speed With the DFS3 you are always sure to have the latest firmware on your device. Our cloud-based software AMETEK Device Agent helps you identify the latest firmware and get it updated in only 60 sec.

Versatility and Flexibility All the DFS3s have an internal Loadcell and TWO external transducer inputs. A Test Station could be configured and set up with 3 transducers.

The DFS3 manages and interfaces with one sensor at a time. With FIVE Test Setups available, you can pre-configure your tests with the required transducer. This simplifies and improves the quality and reliability of your measurements. Fast and intuitive!

Specifications Charts

| Model with AFM Remote Loadcell |

DFS3-250G-AFM-250G |

DFS3-002-AFM-002 |

DFS3-010-AFM-010 |

DFS3-025-AFM-025 |

DFS3-050-AFM-050 |

DFS3-100-AFM-100 |

DFS3-200-AFM-200 |

DFS3-500-AFM-500 |

DFS3-500-AFM-1000 |

$2,455.56

|

$2,455.56

|

$2,455.56

|

$2,455.56

|

$2,376.52

|

$2,376.52

|

$2,376.52

|

$2,376.52

|

$2,376.52

|

| Capacity x Resolution |

0.5 x 0.00001 lbf |

2 x 0.0001 lbf |

10 x 0.001 lbf |

25 x 0.001 lbf |

50 x 0.001 lbf |

100 x 0.01 lbf |

200 x 0.01 lbf |

500 x 0.01 lbf |

1000 x 0.01 lbf

(Gauge 500 x 0.01 lbf) |

| 2.5 x 0.0001 N |

10 x 0.0001 N |

50 x 0.001 N |

100 x 0.001 N |

250 x 0.01 N |

500 x 0.01 N |

1000 x 0.01 N |

2500 x 0.1 N |

5000 x 0.1 N

(Gauge 2500 x 0.1 N) |

| 0.25 x 0.00001 kgf |

1 x 0.00001 kgf |

5 x 0.0001 kgf |

10 x 0.0001 kgf |

25 x 0.001 kgf |

50 x 0.001 kgf |

100 x 0.001 kgf |

250 x 0.01 kgf |

500 x 0.01 kgf

(Gauge 250 x 0.01 kgf) |

| 8 x 0.0001 ozf |

32 x 0.001 ozf |

160 x 0.01 ozf |

400 x 0.01 ozf |

800 x 0.01 ozf |

1600 x 0.1 ozf |

- |

- |

- |

| 250 x 0.01 gf |

1000 x 0.1 gf |

5000 x 0.1 gf |

10000 x 1 gf |

25000 x 1 gf |

50000 x 1 gf |

- |

- |

- |

| Ports |

USB-C |

| Accuracy |

+0.1% of Full Scale |

| Maximum Overload |

150% of Rated Capacity |

| Resolution |

Up to 100,000 resolution points

(according the Unit & Capacity) |

| Peak Capture Rate |

30 kHz |

| Data Sampling |

30 kHz |

| Display Update Rate |

10 Hz |

| Data Save |

Up to 1000 Results (internal 32Go SD Card) |

| Loadcell Thread End |

#10-32 |

5/16-18 UNC |

| Power |

Battery (Lithium Ion) or via the USB-C port |

| Battery Life |

With Dimming On: 40 Hours

With Dimming Off: 30 Hours |

| Operating Temperature |

40 to 110oF (5 to 45oC) |

| Instrument Weight |

1.1 lbs (0.5 kg) |

| Shipping Weight |

4 lbs (2 kg) |

| Included AFM Loadcells Model |

AFM-0250G |

AFM-0002 |

AFM-0010 |

AFM-0025 |

AFM-0050 |

AFM-0100 |

AFM-0200 |

AFM-0500 |

AFM-1000 |

| Capacity x Resolution |

0.5 x 0.00001 lbf |

2 x 0.0001 lbf |

10 x 0.001 lbf |

25 x 0.001 lbf |

50 x 0.001 lbf |

100 x 0.01 lbf |

200 x 0.01 lbf |

500 x 0.01 lbf |

1000 x 0.01 lbf |

| 2.5 x 0.0001 N |

10 x 0.0001 N |

50 x 0.001 N |

100 x 0.001 N |

250 x 0.01 N |

500 x 0.01 N |

1000 x 0.01 N |

2500 x 0.1 N |

5000 x 0.1 N |

| 0.25 x 0.00001 kgf |

1 x 0.00001 kgf |

5 x 0.0001 kgf |

10 x 0.0001 kgf |

25 x 0.001 kgf |

50 x 0.001 kgf |

100 x 0.001 kgf |

250 x 0.01 kgf |

500 x 0.01 kgf |

| 8 x 0.0001 ozf |

32 x 0.001 ozf |

160 x 0.01 ozf |

400 x 0.01 ozf |

800 x 0.01 ozf |

1600 x 0.1 ozf |

- |

- |

- |

| 250 x 0.01 gf |

1000 x 0.1 gf |

5000 x 0.1 gf |

10000 x 1 gf |

25000 x 1 gf |

50000 x 1 gf |

- |

- |

- |

| Strain |

0.33 |

0.33 |

0.33 |

0.38 |

0.15 |

0.20 |

0.20 |

0.20 |

0.30 |

| Accuracy: |

+0.1% of Full Scale |

| Tare Capacity: |

110% of Rated Capacity |

| Maximum Overload: |

150% of Rated Capacity |

| Resolution: |

Up to 100,000 points of resolution (Adjustable depending on Capacity & Units) |

| Peak: |

1 kHz |

| Sampling: |

4 kHz |

| Connection thread size: |

Male - #10-32 |

Female - 1/4 -28 UNF |

Female - 1/2 -20 UNF |

| Operating Temperature: |

40oF to 110oF (5oC to 45oC) |

| Instrument Weight: |

1.1 lbs (0.5 kg) |

| Shipping Weight: |

4 lbs (2 kg) |

| Warranty: |

2 Years |

| Included Accessories: |

SPK-FMG-12A - Hook

SPK-FMG-11A - Flat Adapter |

SPK-FMG-12C - Hook

SPK-FMG-11B - Flat Adapter

SPK-DFS-R-139 - Thread Adapter 1/4-28M to 5/16-18M |

SPK-FMG-12C - Hook

SPK-FMG-11B - Flat Adapter

13048 - Thread Adapter 1/4-28F to 5/16-18F

17162 - Thread Adapter 5/16-18M to 1/2-20M |

AQM

When combined with the DFS3, these rugged and accurate sensors turn your force gauge into a torque measurement device: no need to purchase another gauge. As is the case with the

dedicated loadcells, the gauge may be handheld or used in diverse remote configurations with the straight cable of app. 9ft (2.8M) .

This configuration also offers the flexibility of having both a force and a torque measurement in a single gauge. This is the unit to select for maximum flexibility: one unit and interchangeable

sensors can do it all. The gauge will operate the same as if it were an integral loadcell and all functions will operate normally.

The Chatillon® AQM series Torque Transducers are designed to operate in both clockwise and counterclockwise directions using strain gauge technology and an accuracy better than

0.3% of full scale is now possible for all detachable AQM Torque Transducers. All AQM Torque Transducers are calibrated in both clockwise and counterclockwise

directions tabulated on the NIST calibration certificate.

Note: Ideally when measuring Torque, the Torque Transducer should be

placed so that the torque loads always passes through its center while

minimizing lateral forces.

Important: The requirements to accomplish this are for the Torque to be

applied centrally while keeping the best possible rigid retaining surface.

Calibration Certificate for AQM Torque Transducers The calibration of the AQM Torque Transducer is carried out with the greatest care by our metrology experts. All the AQMs are delivered with a calibration certificate and a statement of Clockwise and Counterclockwise Torque measurements.

| Model with AQM Remote Torque Loadcell |

DFS3-002-AQM-0003 |

DFS3-010-AQM-0012 |

DFS3-050-AQM-0050 |

DFS3-100-AQM-0100 |

DFS3-200-AQM-0200 |

$2,976.16

|

$2,976.16

|

$2,976.16

|

$2,976.16

|

$2,976.16

|

| Capacity x Resolution |

3 x 0.0001 Lbf.in

(Gauge 2 x 0.0001 lbf) |

12 x 0.0001 Lbf.in

(Gauge 10 x 0.001 lbf) |

50 x 0.001 Lbf.in

(Gauge 50 x 0.001 lbf) |

100 x 0.001 Lbf.in

(Gauge 100 x 0.01 lbf) |

200 x 0.01 Lbf.in

(Gauge 200 x 0.01 lbf) |

35 x 0.001 N.cm

(Gauge 50 x 0.001 N) |

125 x 0.001 N.cm

(Gauge 100 x 0.001 N) |

500 x 0.01 N.cm

(Gauge 500 x 0.01 N) |

1000 x 0.01 N.cm

(Gauge 1000 x 0.01 N) |

2000 x 0.1 N.cm

(Gauge 2500 x 0.1 N) |

1 x 0.00001 kgf

(Gauge 1 x 0.00001 kgf) |

5 x 0.0001 kgf

(Gauge 5 x 0.0001 kgf) |

25 x 0.001 kgf

(Gauge 25 x 0.001 kgf) |

50 x 0.001 kgf

(Gauge 50 x 0.001 kgf) |

100 x 0.001 kgf

(Gauge 100 x 0.001 kgf) |

3500 x 0.1 g.cm

(Gauge 5000 x 0.1 gf) |

12500 x 0.1 g.cm

(Gauge 10000 x 0.1 gf) |

50000 x 1 g.cm

(Gauge 50000 x 1 gf) |

- |

- |

50 x 0.001 Oz.in

(Gauge 32 x 0.001 ozf) |

192 x 0.01 Oz.inbr>(Gauge 160 x 0.01 ozf) |

800 x 0.01 Oz.in

(Gauge 800 x 0.01 ozf) |

1600 x 0.1 Oz.in

(Gauge 1600 x 0.1 ozf) |

- |

| Ports |

USB-C |

| Accuracy |

+0.1% of Full Scale |

| Maximum Overload |

150% of Rated Capacity |

| Resolution |

Up to 100,000 resolution points

(according the Unit & Capacity) |

| Peak Capture Rate |

30 kHz |

| Data Sampling |

30 kHz |

| Display Update Rate |

10 Hz |

| Data Save |

Up to 1000 Results (internal 32Go SD Card) |

| Loadcell Thread End |

#10-32 |

5/16-18 UNC |

| Power |

Battery (Lithium Ion) or via the USB-C port |

| Battery Life |

With Dimming On: 40 Hours

With Dimming Off: 30 Hours |

| Operating Temperature |

40 to 110oF (5 to 45oC) |

| Included AQM Torque Transducers Model |

AQM-003 |

AQM-012 |

AQM-050 |

AQM-100 |

AQM-200 |

| Capacity x Resolution |

3 x 0.0001 Lbf.in |

12 x 0.0001 Lbf.in |

50 x 0.001 Lbf.in |

100 x 0.001 Lbf.in |

200 x 0.01 Lbf.in |

| 35 x 0.001 N.cm |

125 x 0.001 N.cm |

500 x 0.01 N.cm |

1000 x 0.01 N.cm |

2000 x 0.1 N.cm |

| 3.5 x 0.0001 kg.cm |

12.5 x 0.0001 kg.cm |

50 x 0.001 kg.cm |

100 x 0.001 kg.cm |

200 x 0.01 kg.cm |

| 3500 x 0.1 g.cm |

12500 x 0.1 g.cm |

50000 x 1 g.cm |

100000 x 1 g.cm |

200000 x 10 g.cm |

| 0.35 x 0.00001 N.m |

1.25 x 0.00001 N.m |

5 x 0.0001 N.m |

10 x 0.0001 N.m |

20 x 0.001 N.m |

| 50 x 0.001 Oz.in |

192 x 0.01 Oz.in |

800 x 0.01 Oz.in |

1600 x 0.1 Oz.in |

3200 x 0.1 Oz.in |

| Torsion |

3o |

3o |

3o |

3o |

3o |

| Accuracy: |

+0.3% of Full Scale |

| Tare Capacity: |

10% of Rated Capacity |

| Maximum Overload: |

150% of Rated Capacity |

| Resolution: |

Up to 100,000 points of resolution (adjustable depending on Capacity & Units) |

| Peak: |

1 kHz |

| Sampling: |

4 kHz |

| Display: |

10 Hz |

| Socket Adapter: |

3/8" (9.5mm) Square Female |

| Mandrel Max Opening: |

0.06 to 0.40" (1.6 to 10mm) |

0.08 to 1.20" (2 to 30mm) |

| Operating Temperature: |

40oF to 110oF (5oC to 45oC) |

| Instrument Weight: |

1.1 lbs (0.5 kg) |

| Shipping Weight: |

4 lbs (2 kg) |

| Warranty: |

2 Years |

| Included Accessories: |

SPK-DTG-037 - 1/4"(6.35mm ) square to Hex Socket Bit & Jacobs tightening key |

SPK-DTG-039 - 1/2"(12.70mm ) square to Hex Socket Bit & Jacobs tightening key |

Accessories

Supplied Ready-To-Go

Regardless of the configuration, your DFE3 is supplied ready-to-go. The gauge and accessories are supplied in a durable carrying case that is designed for all components

including adapters and a USB charger. The units are powered by an internal, rechargeable Lithium-Ion battery. The compliment of adapters is comprehensive

and includes a hook, compression tip, pointed tip, chisel tip, and a notch tip: everything you need to get started.

Included Accessories List

- Chisel Point, 110 lbf. SPK-FMG-008A

- Chisel Point, 550 lbf. SPK-FMG-008B

- Point Adapter, 110 lbf. SPK-FMG-009A

- Point Adapter, 550 lbf. SPK-FMG-009B

- Notch Adapter, 110 lbf. SPK-FMG-010A

- Notch Adapter, 550 lbf. SPK-FMG-010B

- Flat Adapter, 110 lbf. SPK-FMG-011A

- Flat Adapter, 550 lbf. SPK-FMG-011B

- Hook, 50 lbf. SPK-FMG-012A

- Hook, 110 lbf .SPK-FMG-012B

- Hook, 550 lbf .SPK-FMG-012C

- Carrying Case. SPK-DF-118

- Battery Charger, Universal, with Cable . SPK-DF3-UNIV

Full Accessories List

- Chisel Point, 110 lbf. SPK-FMG-008A

- Chisel Point, 550 lbf. SPK-FMG-008B

- Point Adapter, 110 lbf. SPK-FMG-009A

- Point Adapter, 550 lbf. SPK-FMG-009B

- Notch Adapter, 110 lbf. SPK-FMG-010A

- Notch Adapter, 550 lbf. SPK-FMG-010B

- Flat Adapter, 110 lbf. SPK-FMG-011A

- Flat Adapter, 550 lbf. SPK-FMG-011B

- Hook, 50 lbf. SPK-FMG-012A

- Hook, 110 lbf . SPK-FMG-012B

- Hook, 550 lbf . SPK-FMG-012C

- Extension Rod, 6" (152mm), #10-32. SPK-FMG-013A

- Extension Rod, 6" (152mm), 5/16-18. SPK-FMG-013B

- Carrying Case. SPK-DF-118

- Load Cell Shaft Protector. SPK-DFG3-001

- #10-32 to 5/16-18 Adapter. P-10020

- RS232 Cable, 10' (3m). SPK-DF-RS232

- Pistol Grip. SPK-FMG-141

- Swivel Hook, 50 lbf . ML3867

- Swivel Hook, 110 lbf. ML3850

- Swivel Hook, 225 lbf. ML3869

- Swivel Hook, 550 lbf . ML3868

- Hook, Latch NC002500

- Force Test DF2 & DF3 Software. SPK-DF-FORCETEST

Handle Assembly, DFE3/DFS3. SPK-DF3-HANDLE

- Handle Assembly, DF3 Series. 6873

- Grip Handle, MSC/FCE Rev. A. NC002825

- Screw, Flat Head Socket Cap Rev. –. E08-257

5/8 Eye End Kit with Grip Pin for Gauges. SPK-TCM-001

- Phan. 5/8 Eye End Kit with. SPK-TCM-001/PHAN

- Grip Pin for Gauges

- Shaft, Load Cell to 5/8 Eye End, 5/16-24M . NC003235

- to 5/16-18M Rev A

- Upper Eye End Adapter, 5/8" to 5/16-18F Rev A. NC003236

- Locking Ring Rev –. NC003140

- Locking Ring – Eye End, 5/16-18F Rev A. NC003237

- Use PIT/0169/00 Pin, Small Grip Rev 5. NC000612

- Adapter, 5/16-18M to 5/16-18F THRD. NC003254

- for 5/8 Upper Eye End, DFG3

- Adapter, 5/16-18M to 10-32F THRD. NC003255

- for 5/8 Upper Eye End, DFG3

Kit, DF Metric Couplers #10-32_M6; SPK-TCM-033

- 5/16-18_M6; M8_5/16-18

- Coupling #10-32 Female to M6x1mm Female Rev –. NC002652

- Coupling 5/16-18 Female to M6x1mm Female Rev –. NC002658

- Adapter, Threaded, M8x1.25 to 5/16x18, DFG3. NC003256

Battery Charger, Universal, with Cable . SPK-DF3-UNIV

- Cable, USB-C/USB-A, 3 FT, Black . 6885

- Adapter, Wall Mount, AC/DC, 5V, 5W, USB-A . 6886

- Kit, AC Adapter for P/N 6886 . 6887

SPK-TCM-001 The redesigned grip and fixture connection kit offers more flexibility with a wide variety of fixtures.

Included Accessories

| Part No. |

Image |

Description |

Capacity |

| SPK-FMG-008A |

|

Chisel Point |

100 lbf (500 N) |

| SPK-FMG-008B |

|

Chisel Point |

500 lbf, 2.5 kN |

| SPK-FMG-009A |

|

Point Adapter |

100 lbf (500 N) |

| SPK-FMG-009B |

|

Point Adapter |

500 lbf, 2.5 kN |

| SPK-FMG-010A |

|

Notch Adapter |

100 lbf (500 N) |

| SPK-FMG-010B |

|

Notch Adapter |

500 lbf, 2.5 kN |

| SPK-FMG-011A |

|

Flat Adapter #10-32 |

100 lbf 500 N |

| SPK-FMG-011B |

|

Flat Adapter 5/16-18F |

500 lbf, 2.5 kN |

| SPK-FMG-012A |

|

Hook, Low Capacity #10-32 |

50 lbf 225 N |

| SPK-FMG-012B |

|

Hook, Medium Capacity #10-32 |

100 lbf 500 N |

| SPK-FMG-012C |

|

Hook, Stationary 5/16-18 |

500 lbf, 2.5 kN |

| SPK-FMG-013A |

|

Extension Rod, 6” (152mm), Low Capacity (#10-32) |

100 lbf 500 N |

| SPK-FMG-013B |

|

Extension Rod, 6” (152mm) (5/16-18F) |

500 lbf, 2.5 kN |

| SPK-DF2-UNIV |

|

Universal Battery Charger |

- |

| SPK-DF-118 |

|

DFX Series Carrying Case |

- |

| SPK-DF-RS232 |

|

RS232 Cable, 10’ (3m) |

- |

| SPK-DF3-HANDLE |

|

Handle Assembly for DFE3 and DFS3 |

- |

AFM with the motorized TCM

Get greater flexibility in application solutions

To benefit from a more stable and reliable test speed, the external AFM loadcells can be combined with a TCM Motorized Test Stand. This helps to eliminate any variables that might impact the force readings and offers an ideal solution for force measurement testing. The TCM series is well adapted for production environments and attached with the DFS3 digital force gauges makes tensile, compression, peel, and flexural testing of your samples an easy task.

In this solution, you get a powerful stand-alone solution for product testing, where the DFS3 force gauge can display the TCM travel for easy positioning of the moving crosshead. The TCM will stop at break or stop at the limit set on the gauge. This solution is also ideal where repeated measurements are required. Here, the TCM series will ensure that the test is carried out in exactly the same way every time, thus making data collection easier and more comparable.

Benefits with the ForceTest software

Adding the Chatillon ForceTest software will power up your TCM Series force testing solution and will turn your analysis into a fast and simple process. By combining the DFS3 force gauge and the ForceTest software with the TCM Series you obtain:

- Unique solution with powerful and modern UI in ForceTest software

- Plotting of Force (DFS3)

- Setups for Force (Tension or Compression) Torque, Friction and Peel

- Library of results and calculations (ForceTest):

- Peak (T & C)

- Maximum; Minimum; Average for complete test or, on a specific area of research

- Friction test setup with COF results

- Peeling test setup with peeling resistance results

- Selectable Break detection for either software or DF3 readings

- Torque test setup

- Adjustable data rate

- Live graph with autoscaling

- Statistics

- Export to XLS or CSV and PDF report

- Report Designer

- Validation mode for importing known data set in CSV format. Useful in IQ/OQ installation process

Calibration Certificate for AFM Loadcells

The calibration of the AFM Loadcells is carried out with the greatest care by our metrology experts. All our AFMs are delivered with a calibration certificate and a statement of Tensile and Compressive measurements.

|

|